3D Printer Parts: Essential Components and How to Choose the Right Ones

You need many 3D Printer Parts to make your printer work well in businesses and factories. These important parts are the frame, extruder, hotend, print bed, stepper motors, mainboard, power supply, cooling fans, belts, pulleys, bearings, heating elements, display/interface, and accessories.

Experts say knowing about each part helps you make your printer more reliable. It also makes upgrades easier and helps you not waste money. This knowledge lets you pick parts that work together and get the most value when you buy them.

Key Takeaways

- Learn about the main parts of a 3D printer. These include the frame, extruder, hotend, and print bed. Each part helps make prints look good and work well.

- Pick strong parts that fit your printing needs. This helps your printer work better. It also stops problems like warping or failed prints.

- Take care of your 3D printer parts often. This stops sudden breakdowns. It also helps your printer last longer.

- Check if parts work together before you buy them. Making sure all parts fit saves time and money later.

- Buy from trusted suppliers and think about upgrades. Good suppliers give you strong parts. Upgrades can make your printer work better and faster.

Essential 3D Printer Parts

Frame

The frame is the main support for your 3D printer. It holds all the parts together and keeps them steady. A strong frame helps stop shaking, so your prints look better. You need a sturdy frame to guide the extruder and print bed as they move.

|

Function/Role |

Description |

|---|---|

|

Structural Support |

Holds all parts and keeps the printer steady. |

|

Vibration Reduction |

Stops shaking for better prints. |

|

Motion Guidance |

Helps the printer move in all directions. |

|

Material Types |

Aluminum, plastic, steel-each is strong in different ways. |

Common Frame Materials:

Aluminum extrusions are light, strong, and easy to change.

Sheet metal is tough and good for small printers.

Acrylic or plywood costs less but is not as strong.

Plastic is cheap and light but not very sturdy.

Tip: If you use your printer a lot, pick aluminum or steel frames. They last longer and help your prints stay the same every time.

Extruder

The extruder pushes filament into the hotend and controls how much goes in. You need a good extruder to make sure the filament comes out evenly. The kind of extruder you use changes what materials you can print and how neat your prints look.

|

Extruder Type |

Description |

Impact on Print Quality & Compatibility |

|---|---|---|

|

Direct Drive |

Sits close to the hotend for better control. |

Great for soft filaments and neat prints. |

|

Bowden |

Sits farther away and uses a tube. |

Lighter but not as exact, can affect prints. |

|

Single-gear |

Simple but can slip with tough filaments. |

Not always reliable for all materials. |

|

Dual-gear |

Holds filament on both sides. |

Works well with more types of filament. |

Direct drive extruders are more exact and work with soft filaments.

Bowden extruders are lighter and faster but less exact.

Dual-gear extruders are strong and work with many materials.

Note: If you want less downtime, use dual-gear or direct drive extruders. They work with more filaments and need less fixing.

Hotend

The hotend melts the filament and keeps it at the right heat. You need a good hotend to keep the temperature steady and use more materials. Hotends have a nozzle, heat block, heat break, and heat sink.

Parts: Nozzle, heat block, heat break, heat sink.

Types: Plastic-lined (PTFE) for regular plastics; all-metal for hotter plastics.

Temperature Control: Good hotends keep the heat steady for better prints.

Plastic-lined hotends are best for PLA and ABS. All-metal hotends work with hotter plastics like polycarbonate and nylon. All-metal hotends stay hot without problems and are good for tough jobs.

If you print a lot, all-metal hotends save money. They let you use stronger plastics and last longer.

Print Bed

The print bed holds your model while it prints. The bed's material and heat help your print stick and finish well.

Natural fabric beds help prints stick better than fake ones.

Heated beds (55-70°C) help PLA and other plastics stick.

Kapton tape and glue sticks help even more.

|

Material |

Adhesion |

Cost |

Lifespan |

|---|---|---|---|

|

Glass |

Good |

Medium |

Long |

|

PEI Sheet |

Excellent |

High |

Long |

|

Aluminum |

Good |

High |

Long |

|

Acrylic |

Fair |

Low |

Short |

If you want fewer failed prints, use heated beds and good surfaces. This saves time and money.

Stepper Motors

Stepper motors move the print head and bed. You need strong and exact motors for good prints.

|

Specification |

Details |

|---|---|

|

Holding Torque |

0.9° motors can be as good or better than 1.8°. |

|

Torque Stiffness |

0.9° motors fix small mistakes in position. |

|

Microstepping Effect |

More steps mean less power for each step. |

|

Speed Requirements |

0.9° motors need more signals, which can slow them. |

|

Voltage Requirements |

0.9° needs 24V or more, 1.8° needs 12V. |

|

Temperature |

They work best at 60-80°C. |

|

Driver Matching |

Use the right driver for the best results. |

Pick motors with strong holding power and match them with the right drivers for the best prints.

Mainboard

The mainboard is the brain of your printer. It tells all the 3D Printer Parts what to do and when. New boards are faster and have more features.

Faster boards make your printer work quicker.

Better stepper drivers make the printer quieter and smoother.

Wi-Fi and updates make it easier to use.

AI and green features help save energy.

For business, pick mainboards that are fast and easy to upgrade. This helps your printer last longer.

Power Supply

The power supply gives electricity to all 3D Printer Parts. You need a safe and steady power supply to stop problems.

Big printers need power supplies over 20 Amps at 12V.

Special parts keep you safe from electric shocks.

DC power supplies are steady but can cost more.

Always use power supplies that are certified safe. This keeps you and your printer safe.

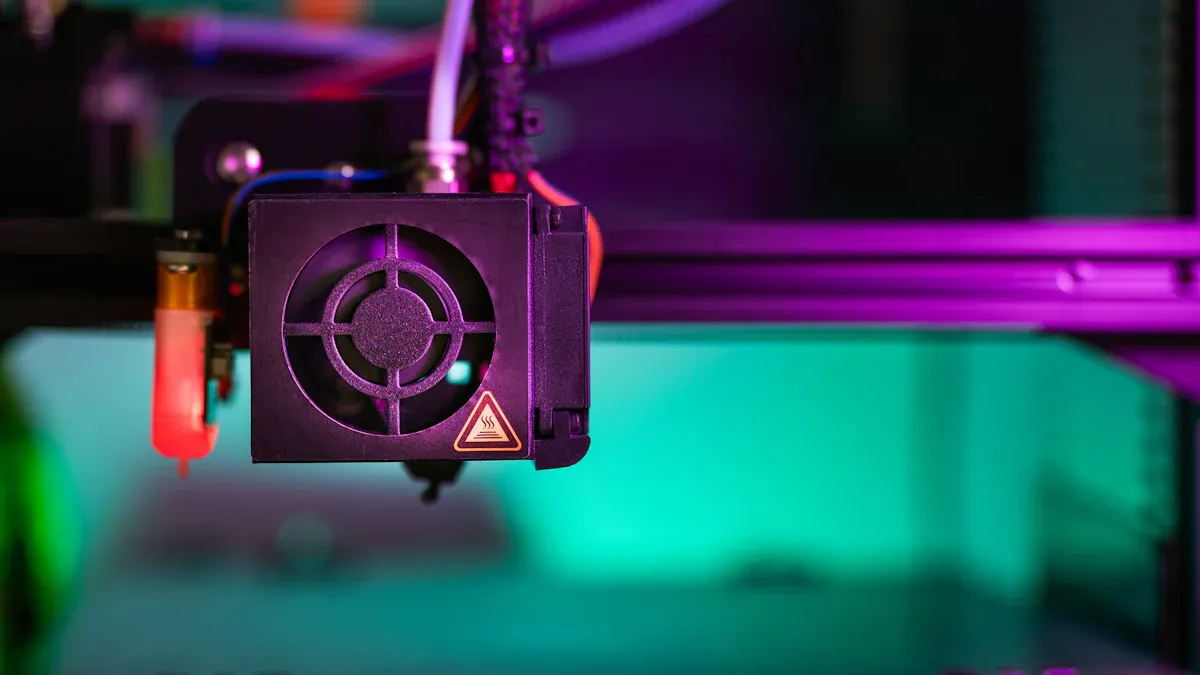

Cooling Fans

Cooling fans keep the hotend, print bed, and prints cool. Good cooling helps layers stick, makes prints smooth, and keeps sizes right.

Axial fans cool the hotend and move air around.

Radial fans cool parts and blow air in one spot.

Cross flow fans spread air in closed printers.

Layer adhesion: Cooling makes layers harden fast.

Surface finish: Fast cooling makes prints smoother.

Dimensional accuracy: Even cooling stops warping.

Print speed: Good cooling lets you print faster.

Check your fans often to stop overheating and help your printer last longer.

Belts and Pulleys

Belts and pulleys help move parts of the printer. You need the right tightness for smooth and exact movement.

Loose belts make layers shift and prints look bad.

Tight belts wear out fast or can break.

Check belts often to keep them working right.

|

Material |

Accuracy |

Maintenance |

Cost |

|---|---|---|---|

|

Rubber |

Good |

Medium |

Low |

|

Reinforced |

Excellent |

Low |

Medium |

|

Steel |

Best |

Low |

High |

For business, reinforced belts and good pulleys help your printer work better and break less.

Bearings

Bearings help the printer move smoothly and cut down on rubbing. You need good bearings for quiet and exact prints.

Polymer bushings are quiet but not very exact.

High-precision bearings make prints more accurate.

Low-friction bearings stop sticking and need less care.

Thrust bearings hold up heavy parts, good for Z-axis.

Flanged bearings help mount and guide belts.

Bushing bearings are light and easy to care for.

Needle bearings are small but can hold a lot.

Pick bearings that fit your printer's needs for the best results.

Heating Elements

Heating elements warm up the hotend and print bed. You need heaters that keep the heat steady for good prints.

PTC cartridge heaters stop getting too hot by themselves.

Good heaters use less power.

Fast heating and cooling help you print faster.

In 3D printing, keeping the right heat is important. It helps your prints stick and look good.

Display/Interface

The display/interface lets you run and watch your printer. New screens are easy to use, load fast, and have smart tools.

Smart slicers pick the best settings for you.

STL Editor checks if your model is ready.

Quick printer pick and better workflow.

Better mobile use and admin tools.

For business, good interfaces make work faster and training easier.

Accessories

Accessories help you take care of your printer and make it work better. Some important ones are:

Digital calipers

Better build surfaces (PEI sheet, glass bed)

Filament dryer

Good tweezers and pliers

Tools to remove prints (spatula, scraper)

PTFE tubing and fittings

Silicone hotend sock

3D printer enclosure

OctoPrint setup

Z-axis lubricant

Deburring tool

Multi-material upgrade

Filament storage

Buying good accessories means less time fixing things and better results from your 3D Printer Parts.

3D Printer Parts and Print Quality

Impact of Each Part

When you pick a 3D Printer Part, you change print quality. Every part helps decide how your finished item looks and works. For example, FTTH projects need connectors that fit just right. If stepper motors or belts slip, parts will not fit together. In data centers, cable trays should have smooth surfaces. Bad cooling fans or weak bearings make rough spots and weak areas.

|

Feature Evaluated |

FDM Technology Result |

Print Quality Impact |

|---|---|---|

|

Dimensional Deviation |

Low |

High accuracy for fit |

|

Geometrical Consistency |

Stable |

Reliable repeatability |

Tip: Good motors, frames, and hotends help stop mistakes in size and rough prints. This saves you time and money because you fix less.

Material Compatibility

You need to use the right 3D Printer Parts with the right filament. Overhead line jobs use strong plastics like ABS or PEEK. These need hotends and beds that get very hot. If you use a direct drive extruder, you can print soft filaments like TPU with fewer jams.

|

Compatibility Factor |

Description |

|---|---|

|

Temperature Capabilities |

Reach high temps for tough filaments (PEEK, ABS) |

|

Extruder Type |

Direct drive for flexible filaments (TPU) |

|

Build Volume and Bed Adhesion |

Heated beds prevent warping for large prints |

Note: Always check if your printer works with the filament you want. This helps stop warping, splitting, and failed prints.

Reliability Factors

You want your printer to work without stopping. Mechanical reliability is very important for businesses. If you print strong parts, like brackets for data centers, you need steady results. Problems can be warping, weak overhangs, or cracks in resin prints.

|

Reliability Factor |

Description |

|---|---|

|

Mechanical reliability |

Durable parts reduce downtime |

|

Operational uptime |

Fewer breakdowns mean more output |

|

Software security and integration |

Stable software keeps jobs running |

|

Print consistency |

Uniform results boost ROI |

Splitting

Warping

Size mistakes

Rough spots

Cracking

Pick strong 3D Printer Parts and check your printer often. You will have less downtime and get more value from your printer.

Choosing the Right 3D Printer Parts

Assessing Needs

First, think about what you want to make. Your business goals matter too. Different 3D Printer Parts work for different jobs. Pick parts that fit your work. Use this table to help compare important things:

|

Criteria |

Description |

|---|---|

|

Type of Filament |

Pick parts that work with your filament. This helps with strength or looks. |

|

Price |

Think about how much you pay now and later. This includes all costs for your work. |

|

Total Cost of Operation |

Add up materials, power, fixing, and software updates. |

|

Brand Reliability |

Good brands give better help and last longer. |

|

Print Quality |

High-quality parts make prints look nicer. |

|

Accuracy |

Precise parts make sure things fit and work right. |

Tip: Match your choices to how much you print and how good you want your prints to be.

Compatibility

Make sure all 3D Printer Parts work together. If parts do not match, your printer may stop or print badly. Check what the maker says about voltage, size, and what materials you can use. For big companies, using the same parts in many printers makes fixing and teaching easier.

Upgrades and Kits

Upgrades make your printer work better and faster. Some popular upgrades are:

Ender-3 nozzle upgrades help you print quicker.

Bed leveling mods like BLTouch make setup easier.

All-metal hotend and extruder upgrades last longer.

Tempered glass beds help prints stick better.

The Hyper Speed Upgrade Kit for Raise3D Pro3 Series lets you print up to 350 mm/s. It keeps prints accurate and helps you finish faster.

Supplier Selection

Pick suppliers who know a lot and are reliable. Use this table to compare:

|

Criteria/Standards |

Details |

|---|---|

|

Technical Expertise |

Look for suppliers with certificates and special skills. |

|

Scalability |

Make sure they can handle big orders. |

|

Responsiveness |

Fast replies and quick delivery are important. |

|

Quality Assurance |

Inspectors and tracking help keep prints the same. |

|

Compliance |

OEM certificates and big clients show you can trust them. |

Do not make mistakes like using walls that are too thin or thick. Always check the shape of your part and use the right wall thickness for your printer.

For more help, look at guides about what you need, what materials work, and how much things cost. These steps help you choose well and get the most from your 3D Printer Parts.

If you know what each 3D Printer Part does, you can help your business do better and make more money. People who learn about these parts often get their money back in less than six months and can save a lot. Before you buy or upgrade, think about what you need, make sure parts work together, and look at the costs. Good parts make your prints look better, work faster, and use less energy. To get the best results, talk to trusted sellers, join online groups, and plan upgrades with tips that work.

Some people say they get more than double their money back in five years and almost ten times more with smart choices.

Think about how big your printer is, how often you change materials, and how much care it needs before you buy.

|

Component |

Why It Matters for Making More Money |

|---|---|

|

Printhead/Hotend |

Keeps the right heat for good prints |

|

Stepper Motors |

Moves fast for better work |

|

Electronics |

Makes sure everything runs smoothly |

FAQ

Why should you upgrade your 3D printer parts?

Upgrading your 3D printer parts makes prints look better. It helps your printer work more often and break less. You can finish jobs faster and fix fewer problems. Good parts help your business reach its goals. You spend less time fixing and save money.

Why does compatibility matter when choosing 3D printer parts?

Compatible parts fit together and work well. If parts do not match, your printer can break or mess up prints. Matching parts make upgrades easier and keep things running smoothly. You save time and avoid wasting money on mistakes.

Why do businesses invest in high-quality 3D printer parts?

High-quality parts help printers make good prints every time. They last longer and break less often. This means fewer delays and less waste. Good parts help businesses earn more and stay ahead of others.

Why do cooling fans play a critical role in 3D printing?

Cooling fans keep the printer from getting too hot. They help prints look smooth and stay strong. Fans let you print faster and stop problems like warping. Good cooling means fewer mistakes in your prints.

Why should you regularly maintain your 3D printer parts?

Regular care keeps your printer working well. You stop surprise breakdowns and help parts last longer. Maintenance makes sure prints stay nice and jobs finish on time.