Cost of 3D Printer Material: Price Comparison by Type, Performance, and Applications

You will see many prices for 3D printer materials in 2024. The table below shows common prices for popular choices:

|

Material |

Printing Technology |

Avg. Cost Per 1kg Spool/Bottle |

|---|---|---|

|

PLA |

FDM |

$15 – $40 |

|

ABS |

FDM |

$20 – $50 |

|

PETG |

FDM |

$20 – $60 |

|

Standard Resin |

SLA-Resin |

$20 – $50 |

|

Flexible Resin |

SLA-Resin |

$60 – $200 |

|

PA 12 Nylon |

SLS |

$150 – $250 |

Many things change the Cost of 3D Printer Material for your business:

|

Factor |

Description |

|---|---|

|

Order Volume & MOQ |

Bigger orders make each unit cheaper. |

|

Specification & Customization |

Special specs cost more and take longer. |

|

Material Grade & Purity |

Better grades have higher prices. |

|

Certifications and Quality |

Certified materials lower risk with rules. |

|

Supplier Reputation |

Trusted suppliers ask for more money. |

|

Incoterms |

Shipping rules change the total cost. |

You should look at these costs to get the best value. This helps you talk better with suppliers.

Key Takeaways

Learn about the cost of different 3D printer materials. PLA costs the least. Specialty filaments can cost a lot more.

Buy in bulk to save money. Getting more at once lowers the price per item. It also cuts down on shipping costs.

Pick materials that fit your project. Nylon is strong and good for working parts. PLA works well for test models.

Always look for certifications. Certified materials are high quality. They meet industry rules and keep your business safe.

Remember extra costs like shipping and finishing. These extra costs can change your total budget. Make sure to plan for them.

Cost of 3D Printer Material by Type

Picking the right material for 3D printing is important. It changes how much you spend and how well your project works. You need to know the Cost of 3D Printer Material for each type. This helps you make smart choices, especially if you buy a lot or use it for a long time. Below, you can see the most common materials, their prices, and what they are good for in business.

PLA

PLA is the most used and cheapest filament for FDM 3D printers. Most PLA costs between $15 and $28 for one kilogram. The average price is about $21. Some brands sell PLA for as low as $8.59 per kg. Fancy PLA can cost up to $37.99 per kg. If you buy big spools, like 10kg or 20kg, you save more money.

Eryone 1KG Galaxy Sparkle PLA Filament: $16.64

High Quality Standard PLA Filament 1kg: $11.99

GEEETECH 1kg PLA: $8.59

Geeetech BiColor Silk PLA: $9.99

Tricolor Silk PLA: $37.99

ANYCUBIC High Speed 20KG PLA: $179.28

SUNLU 10KG PLA Plus: $92.33

Tip: PLA works well for fast models, school projects, and cheap runs. You can lower your Cost of 3D Printer Material by using PLA for things that do not need to be very strong.

PLA is easy to print and does not warp much. It is cheap and simple to use, so it is great for making lots of things. For business buyers, PLA is a top pick because it is easy to find and not expensive.

ABS

ABS is another popular material. It is tough and can handle heat. ABS usually costs from $14 to $60 per kilogram. Most good ABS is $20 to $30 per kg. Fancy or special ABS can be $50 to $75 per kg.

Standard ABS: $20–$30 per kg

Premium ABS: $50–$75 per kg

ABS costs a bit more than PLA, but not by much for normal types. You should use ABS for strong models, covers, and parts that need to last. Buying a lot of ABS at once can help you control the Cost of 3D Printer Material for big jobs.

Note: ABS makes fumes when printing, so you need good airflow.

PETG

PETG is strong like ABS but easy to use like PLA. Most PETG costs $20 to $25 per kilogram. PETG is a little more expensive than PLA but is tougher and bends more.

|

Material |

Price Range (per kg) |

|---|---|

|

PETG |

$20 - $25 |

|

PLA |

$15 - $28 |

|

ABS |

$20 - $35 |

PETG is popular for business because it is a good deal for the price. You can buy PETG in big amounts, like 100 or more spools, to save on the Cost of 3D Printer Material. PETG is good for things that need to handle chemicals or hits, like boxes, machine parts, and outdoor stuff.

Nylon

Nylon is strong, bends well, and lasts a long time. The cheapest nylon starts at $30 per kilogram. Good nylon is $60 to $80 per kg. Special nylon, like NylonX or NylonG, can be $100 to $130 per kg or more.

Standard Nylon: $30–$80 per kg

Specialty Nylon: $70–$130 per kg

Nylon 66 is very strong and used for hard jobs, but it costs more. Nylon 6 is cheaper and good for parts that need to bend and not break. Making nylon uses a lot of energy and must follow rules, so the Cost of 3D Printer Material can go up. Nylon is best for gears, bushings, and test parts in cars, planes, and factories.

Resin

Resin is for SLA and DLP printers and makes detailed or special parts. Standard resin costs $15 to $40 per liter. Special resins, like water-washable, flexible, heat-proof, or medical, can be $40 to $600 per liter.

|

Resin Type |

Price Range (per liter) |

|---|---|

|

Standard Resins |

$15 - $40 |

|

Water-Washable Resins |

$20 - $60 |

|

Flexible Resins |

$40 - $100 |

|

Heat Resistant Resins |

$70 - $200+ |

|

Dental/Medical Resin |

$200 - $600 |

|

Jewelry Casting Resin |

$300 - $800 |

Pick resin based on what you need it for. Standard resin is cheap and good for models and small things. Engineering and medical resins cost more but are needed for tough or special jobs. The Cost of 3D Printer Material for resin goes up fast if you need special types, so plan your orders well.

Specialty Filaments

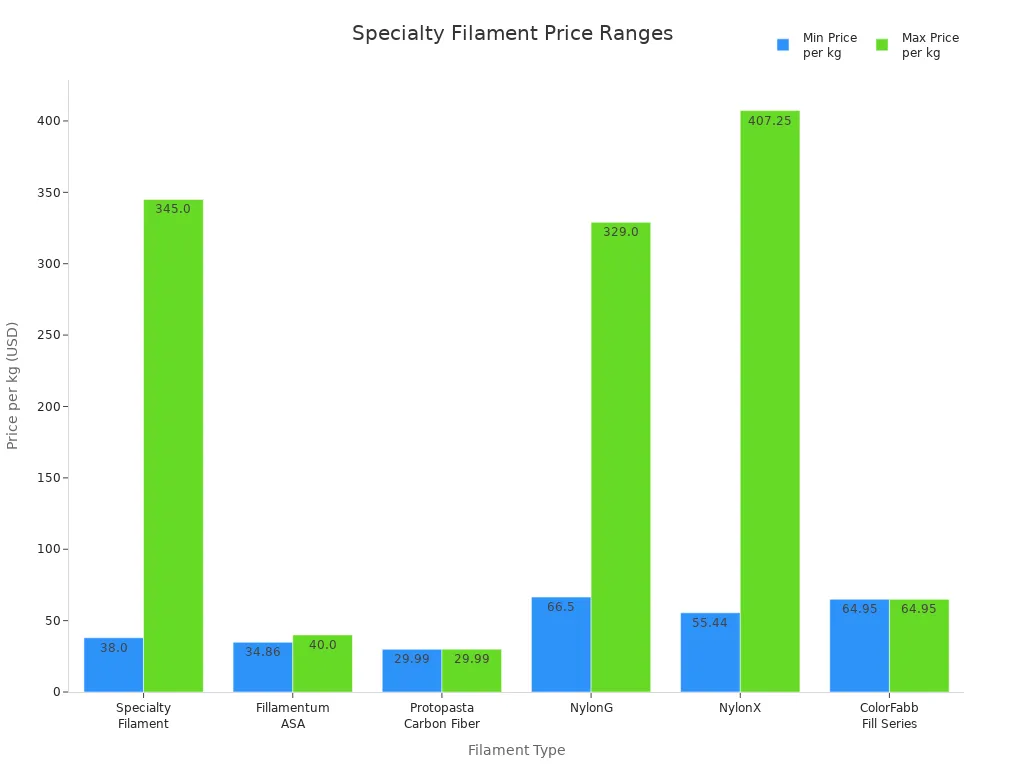

Specialty filaments include carbon fiber, metal, flexible, and mixes. Prices are very different, from $38 to $345 per kilogram for most types. Some, like NylonX and NylonG, can be $407 per kg.

|

Specialty Filament |

Price Range (per kg) |

|---|---|

|

Carbon Fiber |

$29.99 - $407.25 |

|

ASA |

$34.86 - $40.00 |

|

NylonG |

$66.50 - $329.00 |

|

ColorFabb Fill |

$64.95 |

Specialty filaments have special features, like being very strong, able to carry electricity, or bendy. They cost more, but they can help your business make better products. For example, filament tape is cheaper and saves work compared to steel straps, so it can lower costs over time. You should think about the Cost of 3D Printer Material and if the extra features are worth it for your business.

Alert: Specialty filaments need special printer settings and sometimes extra steps after printing, which can make your total cost higher.

Summary Table: Price Ranges and Application Suitability

|

Material Type |

Price Range (per kg/L) |

Best For |

Bulk Savings Potential |

|---|---|---|---|

|

PLA |

$15–$28/kg |

Prototyping, education |

High |

|

ABS |

$20–$30/kg |

Functional parts, enclosures |

High |

|

PETG |

$20–$25/kg |

Mechanical, packaging |

High |

|

Nylon |

$30–$130/kg |

Industrial, automotive |

Moderate |

|

Resin |

$15–$600/L |

High-detail, medical, jewelry |

Moderate |

|

Specialty Filaments |

$38–$407/kg |

Industrial, specialty products |

Low |

You need to look at the Cost of 3D Printer Material for each type. Think about what your project needs, how much you will buy, and what your supplier offers. This helps you spend less and get the most out of your 3D printing.

Performance and Cost Comparison

When you pick a 3D printer material, do not just look at price. You also need to think about strength, flexibility, and durability. These things help your project work well and last longer. They are important for businesses that want good parts and a steady return on investment.

Strength

Strength means how much force a material can take before it breaks. If you want parts that last, check the strength of each material. Stronger materials usually cost more. But they can save money because you will not need to replace them as often.

Here is a table that shows how strength and price go together for popular 3D printer materials:

|

Material Type |

Average Price Range (per Kg) |

Strength Characteristics |

|---|---|---|

|

High-performance polymers |

$500-$800 |

Superior properties, used for demanding jobs |

|

Standard filaments (PLA) |

$10-$100 |

Lower strength, good for simple models |

|

ABS |

$20-$150 |

Good mechanical strength, suitable for enclosures |

|

PETG |

$30-$120 |

Durable, resists chemicals, moderate strength |

|

Flexible materials (TPEs) |

$35-$140 |

High elasticity, not for load-bearing parts |

|

Composite materials |

$35-$250 |

Enhanced strength with additives |

|

Standard resin |

$40-$200 |

Best for detail, not for heavy loads |

|

Tough resin |

$60-$200 |

Similar to ABS, designed for durability |

|

Flexible resin |

$60-$200 |

Rubber-like, used for ergonomic parts |

Tip: For tough jobs, high-performance polymers and composites are best. They cost more but give you strong parts. For simple models, PLA and PETG are cheaper and work well.

Flexibility

Flexibility means a material can bend or stretch without breaking. Pick flexible materials if your part needs to move or take hits. Flexibility changes the price and what you can use the material for.

TPU is good for seals, gaskets, and car parts. It bends well and lasts a long time. It is not too expensive and is easy to find.

Nylon, especially as SLS powder, is strong and flexible. It works for test parts and custom pieces. But nylon can cost more to print and needs careful handling.

Note: Flexible materials like TPU and nylon help your parts last longer. They work better in places where things move a lot. Think about if the extra cost is worth it for your project.

Durability

Durability shows how well a material stands up to use, chemicals, and time. Durable materials mean less fixing, fewer repairs, and longer life for your equipment. Spending more on durability can help you save money later.

|

Benefit |

Explanation |

|---|---|

|

Reduced maintenance and repairs |

Durable parts break less, so you fix them less. |

|

Fewer print failures |

Good materials print better, so you waste less. |

|

Extended machine lifespan |

Durable materials help your printer last longer and cost less over time. |

Alert: If you print parts for factories or outside, durability is very important. Pick materials that can handle chemicals, heat, and hits, even if they cost more at first.

Certification and Quality Standards

You need to make sure your materials meet industry rules. Certifications show your supplier gives you safe and good quality products. For businesses, these papers lower risk and help you follow the rules.

Material Test Reports (MTRs): These reports show what is in each batch and how it acts. You need them for important jobs.

Certificates of Conformance (CoC): These papers prove the product meets your standards.

Industry-Specific Certifications: Rules like AS9100 for planes and ISO 13485 for medical tools are needed for those jobs.

Tip: Always ask your supplier for certification papers before you buy. This keeps your business safe and helps you get the best value for the Cost of 3D Printer Material.

Cost vs. Performance Table for Key Materials

|

Material |

Avg. Price (per kg/L) |

Strength |

Flexibility |

Durability |

Certification Potential |

|---|---|---|---|---|---|

|

PLA |

$15–$28 |

Low |

Low |

Low |

Basic |

|

ABS |

$20–$30 |

Medium |

Low |

Medium |

MTR, CoC |

|

PETG |

$20–$25 |

Medium |

Medium |

Medium |

MTR, CoC |

|

Nylon |

$30–$130 |

High |

High |

High |

MTR, CoC, ISO |

|

Resin |

$15–$600 |

Low-Med |

Low-Med |

Low-Med |

CoC, ISO |

|

Specialty Filaments |

$38–$407 |

High |

Varies |

High |

MTR, CoC, Industry |

You should pick materials that fit your project's needs. Strong, flexible, and durable materials may cost more, but they help you avoid problems and save money in the end. Always check for certifications to make sure you get good quality.

Application-Based Cost Analysis

Prototyping

For prototyping, you want materials that are fast and cheap. ABS, ASA, and Nylon are good choices because they save money. These materials let you try out ideas without spending a lot. Telecom companies use ABS to make quick models of device cases. EPC contractors pick ASA for outdoor models since it does not get damaged by the sun. Nylon is great for testing machine parts that move.

|

Material |

Price Range (per kg) |

Cost Efficiency |

|---|---|---|

|

ABS |

$25 - $100 |

High |

|

ASA |

$25 - $100 |

High |

|

Nylon |

$25 - $100 |

High |

|

Carbon Fiber |

$200 |

Low |

Tip: Buying a lot of material at once saves money. This makes each part cost less when you make many.

Functional Parts

Functional parts must be strong and last long. You can use plastic instead of metal to save money. Many sellers use Nylon for gears and brackets because it is tough. EPC contractors often use ABS for covers and PETG for parts that need to handle chemicals. These choices help make things faster and work better.

|

Factor |

Impact on ROI |

|---|---|

|

Cost Savings |

Using plastic instead of metal costs less. |

|

Manufacturing Efficiency |

Fewer extra steps mean you finish faster. |

|

Product Performance |

Good plastics can be as strong as metal for many jobs. |

|

Lifecycle Advantages |

Plastics do not rust and are lighter, so they last longer. |

Note: If you have big orders or deals with suppliers, you pay less and always have what you need for big jobs.

Artistic Models

Artistic models need to look nice and have smooth details. People like SLA resin for its fine finish and high detail. SLS nylon is good for art you can wear or pieces that fit together. FDM with PLA or ABS is used for big, simple art. Metal 3D printing makes strong and fancy art pieces.

|

Technology |

Description |

Materials |

Key Features |

Best Use Cases |

|---|---|---|---|---|

|

SLA |

Uses a laser to harden resin |

Photopolymer Resin |

Very smooth and detailed |

Fine art, small figures |

|

SLS |

Uses a laser to melt powder |

Nylon (PA12) |

Strong, not shiny |

Wearable art, design |

|

FDM |

Melts plastic filament |

PLA, ABS |

Quick and cheap |

Drafts, simple shapes |

|

Metal 3D Printing |

Melts metal powder |

Stainless Steel, Titanium |

Very strong and fancy |

Sculptures, bases |

|

Composites |

Mixed filaments |

Wood-PLA, Ceramic Resin |

Special textures |

Art that looks natural |

Expensive resins are used for art with lots of detail.

Factories use SLS or FDM for models that need to work well and cost less.

Industrial Use

Big industrial jobs care about price and how much they need. PLA and ABS are the cheapest plastics. Nylon costs more but works better for hard jobs. The most costly are special plastics and metals, which are used for tough work.

|

Type of Material |

Cost Level |

|---|---|

|

Commodity Plastics (PLA, ABS) |

Least Expensive |

|

Engineering-Grade Plastics (Nylon) |

Moderately Priced |

|

High-Performance Plastics (PEEK) |

More Expensive |

|

Metals (Stainless Steel) |

Most Expensive |

Buying in bulk and making deals with suppliers helps you spend less. This keeps your factory running well and lowers risk for big jobs.

Alert: Picking the best material and supplier helps telecom and EPC companies save money and finish projects on time.

Additional Cost Factors

When you make a budget for 3D printing, you need to think about more than just the price of the material. There are other costs that can change how much you spend and what choices you make for your business.

Shipping

Shipping can make your total cost much higher. Sometimes, you might pay up to 20% more just for shipping your filament. If you buy from another country or want your order fast, it will cost even more. Buying a lot at once can help you save money because the shipping cost for each kilogram goes down.

Shipping can add up to 20% to your cost.

Buying in bulk makes shipping cheaper for each kilogram.

Fast or international shipping costs extra.

Tip: Always ask your supplier how much shipping will cost before you order a lot. This helps you plan your money and not get surprised by extra fees.

Brand

The brand you pick changes how much you pay for 3D printer materials. Famous brands cost more because they are known for good quality and being reliable. You get better prints and fewer problems with trusted brands. Cheaper brands might save you money, but you could get bad quality or prints that do not always work.

|

Brand Type |

Price Level |

Reliability |

Quality Control |

|---|---|---|---|

|

Well-known |

High |

High |

Strict |

|

Lesser-known |

Low |

Varies |

Basic |

Note: You should think about both price and trust. Paying more for a good brand can help you waste less and keep your printer working well.

Color and Quality

The color and quality of your material also change the price. Special colors or shiny finishes usually cost more than normal ones. Better quality filaments use nicer materials and are made with more care, so they cost extra. These better materials help your prints come out right and work better.

Special colors and finishes make the price go up.

High-quality filaments cost more because they are made better.

Good quality means your prints fail less often.

Other Cost Factors for B2B Procurement

You should also think about bulk prices, how reliable your supplier is, and if they help you after you buy. Buying a lot at once makes each item cheaper, which is good for big jobs. A good supplier helps you avoid waiting and keeps your work moving. If you have problems, good after-sales help can fix things fast and lower your risk.

Finishing your printed parts adds more cost. You might spend 17% to 100% more time making parts look good. Paying people to finish parts can cost $25,000 to $50,000 each year for every printer you have. If you skip this step, your parts might not look as good or work as well.

Alert: Always remember to add shipping, brand, color, quality, and finishing costs to your budget. These things help you spend less and get more value from your 3D printing.

You should look at the Cost of 3D Printer Material by type, how it works, and what you use it for. This makes it easier to pick the best material for your project and how much you want to spend.

Choose materials that fit what you need and make sure your supplier is trustworthy.

Think about how much you pay now and later to help you save money.

Check if buying a lot costs less and ask for proof that the material is good before you buy.

Making smart choices helps you avoid problems and lets your business get bigger.

FAQ

Why does 3D printer material cost vary so much?

Prices are different because of the type and brand. Quality also changes how much you pay. Special filaments and certified materials cost more money. If you buy a lot at once, each kilogram is cheaper. Shipping and finishing steps can make your total cost higher.

Why should you choose certified 3D printer materials for business?

Certified materials follow important industry rules. This means you have fewer failed prints and less chance of recalls. Certifications help you pass checks and win more jobs. You also get better quality and more trust in your results.

Why is bulk purchasing important for B2B buyers?

Buying in bulk makes each unit cost less. You save money on shipping and get better prices from suppliers. This helps you plan your budget and always have enough for big projects.

Why do some applications require specialty filaments?

Specialty filaments have special features like being strong or flexible. Some can handle heat or tough jobs. You need them for hard work in cars, planes, or medical tools. Regular materials cannot do these special jobs.

Why should you consider post-processing costs in your budget?

Finishing steps make your parts look and work better. You spend extra time and money to finish each part. If you forget these costs, your project can lose money and be late for your customers.