3d printing can take anywhere from a few minutes to several days. The time you need for a 3d printer to finish a print depends on many factors. If you print a small object, the printer works quickly. Large or complex prints need more time because they use more layers and require precise toolpathing. Your 3d printer type also matters. Some printers cure whole layers at once, while others trace every detail. Print settings like layer height and infill density affect how long does it take to 3d print. Thinner layers and denser infill add time, but higher speeds may lower quality. The only way to know exactly how long does it take to 3d print your model is to use slicer software with your chosen settings.

3d printing time factors

When you start a 3d print, several factors decide how long it will take. Understanding these factors helps you plan your projects and set realistic expectations for your 3d printer.

Printer Type

The type of 3d printer you use plays a big role in printing time. FDM printers often print faster because they use thicker layers, usually around 200-250 microns. SLA printers can print with finer layers, like 100 microns, but this increases the time needed. PolyJet printers create very thin layers, sometimes as low as 16 microns, which means high detail but longer print times. Each printer type has its own speed limits and strengths.

Tip: If you want faster prints, choose a printer that supports thicker layers and higher print speed.

Object Size

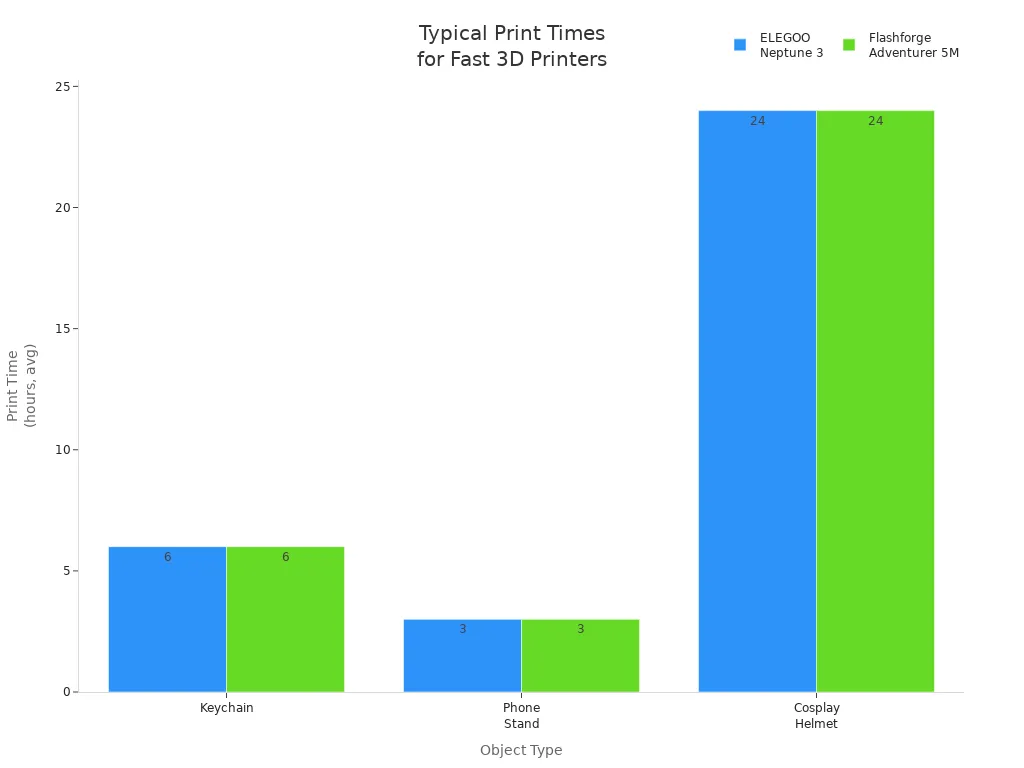

The size of the part you want to print affects the total time. Small objects, like keychains, can finish in 30 minutes to 1 hour. Medium objects, such as phone cases, may take up to 5-6 hours. Large prints, like helmets, can last over 24 hours or even several days. Bigger size means more layers and more time for your 3d printer to work.

Complexity

Complexity also changes how long your print takes. If your model has many details, overhangs, or bridges, the printer needs to make more adjustments. Supports may be needed for tricky shapes, which adds to the printing time. Simple shapes print faster, while high complexity increases both time and material use.

Material

Different materials print at different speeds. For example, PLA can print at 60 mm/s or even faster, while ABS usually prints at 40-60 mm/s. Resin printers do not use the same speed measure, but they often take longer due to the curing process. The material you pick changes how quickly your 3d printer can finish the job.

|

Material |

Typical Print Speed (mm/s) |

Notes |

|---|---|---|

|

PLA |

60 (standard), up to 150+ |

Flexible speed, can go much faster |

|

ABS |

40-60 |

Slightly slower, but similar to PLA |

|

Resin |

N/A |

Curing process, not measured in mm/s |

Print Settings

Your 3d printing settings have a big impact on print time. Lower layer heights give you better quality but take longer. Higher infill percentages make your print stronger but increase time. Print speed settings also matter; higher speeds finish faster but may lower quality. Balancing these settings helps you control both the speed and the final look of your print.

Note: The best way to estimate your 3d printing time is to use slicer software with your chosen settings and model.

how long does 3d printing take

If you want to know how long 3d printing takes, you need to think about the size and detail of your object. The time it takes depends on what you are printing and the settings you use. You can look at real examples for small, medium, and large prints. You will also see how printing with extra detail can make the job take longer.

Small Prints

Small prints, like keychains or simple figures, are the fastest to finish. A basic keychain can print in about 10 to 20 minutes. Some small things, like chess pieces or toys, might take up to an hour. The time depends on layer height, infill, and how long each layer cools. If you make the layer cooling time longer, the print will take more time. Printing many small parts at once also adds time, because each layer must cool before the next one.

You should print small things slowly and at lower heat, around 210°C, with speeds close to 20 mm/s. This helps stop mistakes and gives a smoother finish. If you set the infill to 100% or add more top and bottom layers, the print will take longer. Every printer is a little different, but you should try to balance speed, heat, and cooling for the best results.

Tip: Printing small things slowly and cool helps you get a smooth finish and lowers the chance of problems.

Medium Prints

Medium prints, like phone cases, action figures, or small home items, take more time. These prints usually take from 1 to 6 hours. If your model is more detailed, with sharp corners or thin parts, it can take 12 hours or more. For example, a simple phone case might finish in 1 to 2 hours, but a case with lots of patterns or supports could take much longer.

Some medium prints, like models of body parts, need extra steps like cutting or splitting. These steps help make the file smaller and the print faster. If your model is too big for the printer bed, you may need to shrink it or print it in pieces, which also changes the time. The time for medium prints depends on infill, layer height, and if you need supports. More supports and higher infill make the print take longer.

Large Prints

Large prints, like helmets, cosplay props, or big vases, take the most time. These prints can take from 12 hours to a few days. For example, printing an Iron Man helmet (about 12" x 10" x 11") with 20% infill uses about 580 grams of filament and takes about 48 hours. A vase (8" tall) with 10% infill might take 12 hours, and a gear (5" x 5" x 2") with 40% infill can finish in 6 hours.

Here is a table with some average print times for large objects:

|

Print Item |

Approximate Size |

Infill % |

Filament Used (grams) |

Print Time (hours) |

|---|---|---|---|---|

|

Iron Man Helmet |

12" x 10" x 11" |

20% |

~580g |

48 |

|

Decorative Vase |

8" x 4" |

10% |

~95g |

12 |

|

Gear Mechanism |

5" x 5" x 2" |

40% |

~72g |

6 |

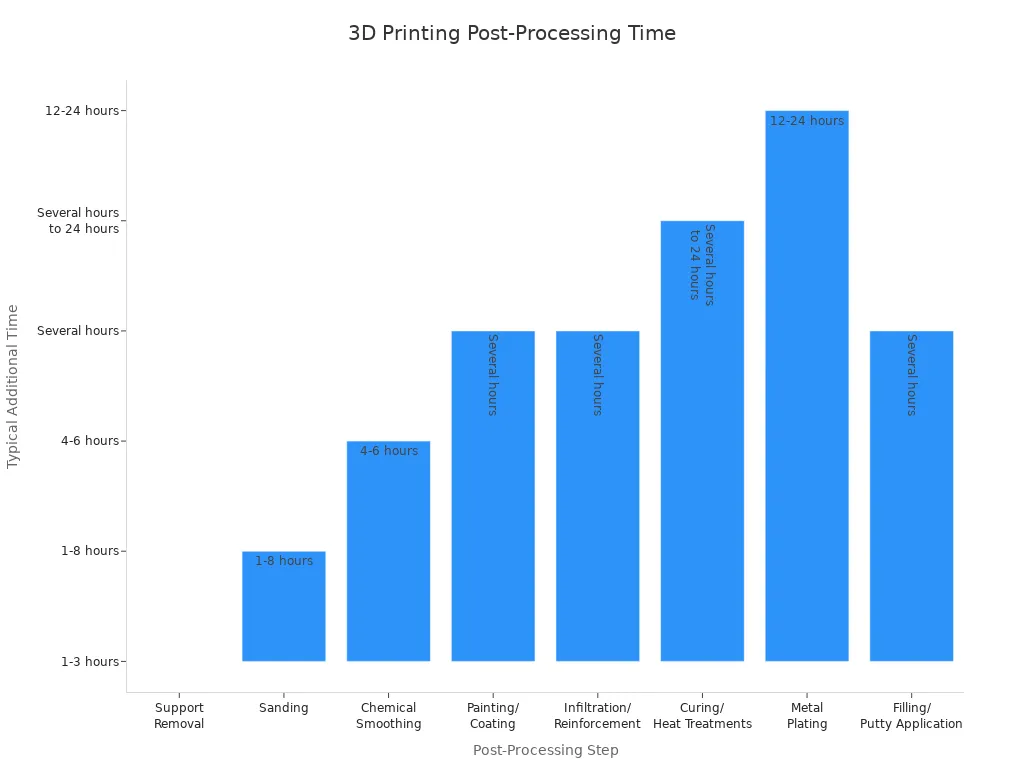

The time for large prints depends on layer height, infill, and how hard the print is. If you use very thin layers, the print will take even longer. Some big, detailed prints can take a few days to finish. Ultra-precision 3d printing uses thin layers and slow speeds for the best quality, but this makes the print take much longer. After printing, you may need to remove supports or sand the object, which adds more time.

Note: Large 3d printers can save time by printing whole parts at once, so you do not need to put pieces together later.

When you plan a project, always think about how long your print will take based on size and detail. The best way to know the exact time is to use slicer software with your settings. This gives you the most accurate guess for your 3d print time.

estimate 3d printing time

Knowing how long a 3d print will take helps you plan. You can use slicer software or online calculators for this. Each tool has good points and some limits.

Slicer Software

Slicer software is the best way to guess print time. You load your STL file into the slicer. The slicer looks at your model and uses your settings. These settings are things like layer height, infill, print speed, and material type. The slicer makes G-code for your printer to follow.

Experts say you should match slicer limits to your printer. This means using the right feedrates, acceleration, and jerk. Doing this makes your time guess better. You can also run a print simulation in the slicer. This lets you see if the guess matches real print time. Some slicers can get machine info from your printer for better results. Still, the real print time may be a bit different. Things like minimum layer time or special macros can change the time.

Note: Slicer software guesses can be close to real print times. But how close depends on your printer and its firmware. Some printers match the slicer's guess well. Others may take longer because of hardware limits.

Online Calculators

Online calculators are a fast way to guess cost and material use. You put in things like filament type, weight, and how long you think the print will take. But these tools cannot guess print time from an STL file. They do not look at your model or make G-code. They use the time you give them or get from your slicer.

Slicer software is still the best way to guess print time. Online calculators help you plan cost, but they are not as good for time.

Tip: Always use slicer software to guess how long your 3d print will take. Use online calculators to check cost and material after you know the print time.

reduce 3d printing time

Reducing the time it takes for a 3D printer to finish a job can help you complete projects faster and use your machine more efficiently. You can use several strategies to make your printing process quicker without losing too much quality.

Adjust Settings

You can change your 3d printing settings to save time. Try increasing the layer height. Thicker layers mean fewer layers to print, so your object finishes faster. For example, moving from a 0.16mm to a 0.28mm layer height can cut print time by almost half, but the surface may look rougher. Lowering the infill percentage also helps. If you use 10% infill instead of 30%, your print will use less material and finish sooner. Simple infill patterns like lines or zigzag print faster than complex ones. Draft mode in slicers can speed up printing for prototypes. Remember, thicker layers and lower infill make prints weaker, so use these settings for models that do not need high strength.

Tip: Use a moderate print speed to keep good bonding between layers and avoid weak spots.

Simplify Model

Simplifying your model can greatly reduce print time. Remove small details that do not affect the final look. Hollow out large parts or add internal cavities to use less material. You can also break big models into smaller pieces for separate printing and easy assembly. Place your model in a way that needs fewer supports. Fewer supports mean less printing and less cleanup later. Use software tools to reduce the number of polygons in your model, which helps the slicer work faster.

Choose Faster Printer

The type of printer you use affects how quickly you finish a print. Some printers can reach high print speeds, letting you complete small objects in minutes and large ones in hours. For example, a fast printer can make a keychain in about 5-7 minutes and a phone stand in 2-4 hours. Industrial models can print even faster, with speeds up to 300 mm/s or more. Regular maintenance keeps your printer running at top speed and prevents slowdowns.

Speed vs. Quality

You must balance print speed and quality for the best results. Higher speeds and thicker layers make printing faster, but the surface may look rough and the object may be weaker. Lower speeds and thinner layers give you smooth surfaces and strong prints, but take much longer. Many users start with slow speeds and test prints, then increase speed until they see defects. Adaptive layer height in slicers can help you keep detail where needed and speed up flat areas. Calibrate your printer and fine-tune settings like retraction and acceleration to keep quality high at faster speeds.

Note: Finding the right balance between print speed and quality depends on your project needs. Quick prototypes can use fast settings, while final models may need slower, high-quality prints.

You will see that printing time can change a lot for each project. Many things affect how long printing takes, like the size of your object, how detailed it is, what material you use, and your printer type. Slicer software helps you know the print time before you start. Try different settings to find a good mix of speed and quality. After printing, you might need more time for cleaning, sanding, or painting. These extra steps can add many hours to your total time.

Printing times change with each design, use, and printer.

Steps after printing, like sanding and curing, add more hours.

FAQ

How can you speed up 3D printing time?

You can increase layer height, lower infill, and use draft mode in your slicer software. Choose simple models and adjust print settings for faster results. Fast printers also help you finish jobs quickly. [1]

What is the most accurate way to estimate 3D printing time?

You should load your model into slicer software and set your print settings. The slicer calculates the time based on your object and chosen options. This method gives you the closest estimate. [2]

Does print quality change if you print faster?

Yes, higher speeds and thicker layers can reduce surface quality and strength. You may see rough edges or weak spots. Slower speeds and fine layers improve quality but increase 3D printing time. [3]

Why do large prints sometimes take days to finish?

Large prints use more layers and material. Complex shapes need supports and slow speeds for accuracy. Ultra-precision settings also add hours or days to 3D printing time. [4]

Can you use online calculators to estimate print time?

Online calculators help you estimate cost and material. They do not analyze your model or print settings. Slicer software remains the best tool for accurate 3D printing time estimates. [5]

Tip: Always check your slicer's preview for the best time estimate before starting a print.

References

[1] 3D Printing Industry, "How to Speed Up 3D Printing," 2023.

[2] All3DP, "How to Estimate 3D Print Time," 2024.

[3] MatterHackers, "Print Quality vs. Speed," 2023.

[4] 3D Insider, "Why Do Large 3D Prints Take So Long?" 2024.

[5] 3Dnatives, "3D Printing Calculators: What Can They Do?" 2023.